05 2025

Abstract: In order to explore the performance of rock wool boards with different densities, four types of rock wool boards with different densities were selected, and tests were carried out on their hygroscopicity, water absorption, high – temperature resistance, thermal conductivity, and tensile strength. The results show that the hygroscopicity rate, water absorption rate, and mass loss rate after high – temperature of the rock wool board decrease with the increase of density. The thermal conductivity of the rock wool board in the dry state increases with the increase of density; the thermal conductivity of the rock wool board in the water – absorbed state decreases with the increase of density. The tensile strength of the rock wool board in the dry state increases with the increase of density; the tensile strength of the rock wool board in the water – absorbed state decreases, and the decrease range decreases with the increase of density. Based on the comprehensive test results, it is recommended to select rock wool boards with densities of 140kg·m⁻³ and 160kg·m⁻³ as exterior wall thermal insulation materials.

Rock wool insulation board is an inorganic non-metallic material with good thermal insulation performance, low thermal conductivity and good durability. Therefore, it is widely used in building exterior walls. Many scholars have studied the performance of rock wool boards. Relevant research shows that the hygroscopicity and thermal conductivity of rock wool boards are greatly affected by environmental temperature and humidity. When the temperature and humidity increase, the hygroscopicity and thermal conductivity increase [1]. When the relative humidity is less than 90%, the moisture absorption rate of the rock wool board is small; in saturated steam, the moisture absorption rate of the rock wool board is large [2]. After the rock wool board is left standing in water for 28 days, both the compressive strength and the tensile strength decrease, and the thermal conductivity of the rock wool board increases in a humid environment [3]. As a thermal insulation material, the performance of rock wool is greatly affected by its density. The higher the density, the more rock wool fiber content, the fewer pores and the greater the thermal conductivity. Exploring the performance of rock wool boards with different densities has an important impact on building energy conservation, insulation and durability [4 – 5].

However, in the existing research, there are few results on the influence of density on the properties of rock wool boards, such as hygroscopicity, water absorption, high – temperature resistance, thermal conductivity, and tensile strength. The author carried out a performance study on four types of rock wool boards with different densities in this field.

1 Test Plan

Select rock wool boards with densities of 100kg·m⁻³, 120kg·m⁻³, 140kg·m⁻³, and 160kg·m⁻³, and conduct tests mainly on moisture absorption, water absorption, high – temperature resistance, thermal conductivity, and tensile strength.

Table 1 Specimen Dimensions

Unit: mm

Performance, size (length × width × thickness)

Hygroscopicity 100 × 100 × 70

Water absorption 100 × 100 × 70

High temperature resistance 100 × 100 × 70

Thermal conductivity coefficient 200 × 200 × 70

Tensile strength 150 × 150 × 70

2 Test Results and Analysis

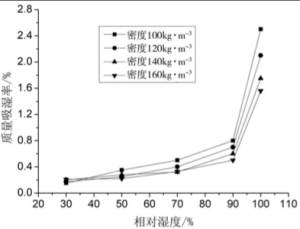

The relationship between the moisture absorption rate of rock wool boards with different densities and relative humidity is shown in Figure 1. As the humidity increases, the moisture absorption rate of the rock wool board increases, and the development and change laws of the moisture absorption rate of rock wool boards with different densities and relative humidity are basically the same. When the relative humidity is 30% – 90%, the moisture absorption rate increases slowly; when the relative humidity is 90% – 100%, the moisture absorption rate increases rapidly, indicating that the moisture absorption rate of rock wool is higher in a high – humidity environment. When the relative humidity is 100%, the moisture absorption rate increases sharply. This is because liquid water condenses on the surface and inside of the rock wool board in a saturated humidity environment, greatly increasing the moisture content [2]. The test results show that as the density of the rock wool board increases, the moisture absorption rate decreases. Because the smaller the density of the rock wool board, the larger the porosity. As the humidity increases, more water molecules penetrate into the pores, resulting in a larger moisture absorption rate.

Figure 1 Relationship between Moisture Absorption Rate of Rock Wool Boards with Different Densities and Humidity

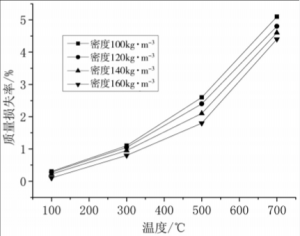

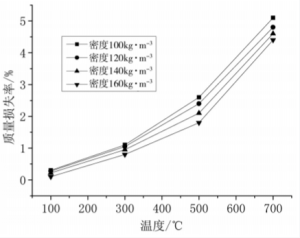

The relationship between the mass loss rate of rock wool boards with different densities and temperature is shown in Figure 3. As the temperature increases, the mass loss rate increases. When the temperature is higher than 300℃, the increase in the mass loss rate is significant. When the temperature reaches 700℃, the mass loss rate reaches 4.4% – 5.1%. The higher the density of the rock wool board, the smaller the mass loss rate.

Figure 3 Relationship between mass loss rate and temperature of rock wool boards with different densities

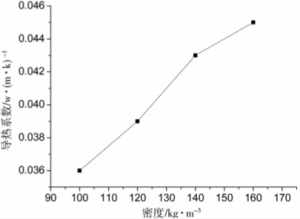

The development and change curves of the thermal conductivity of rock wool boards with different densities in the dry state are shown in Figure 4. As the density increases, the thermal conductivity increases. This is because the higher the density of the rock wool board, the more rock wool fibers it contains, the smaller the internal interconnected porosity, the less air content, and the thermal conductivity of rock wool fibers is much higher than that of air. Therefore, the higher the density of the rock wool board, the greater the thermal conductivity [6].

Figure 4 Thermal Conductivity of Rock Wool Boards with Different Densities in Dry State

The development and change curves of the thermal conductivity of rock wool boards with different densities in the hygroscopic state are shown in Figure 5. The development and change laws of the thermal conductivity of rock wool boards with different densities are inconsistent. When the density of the rock wool board is 100kg·m⁻³ and 120kg·m⁻³, with the increase of relative humidity, the thermal conductivity increases. When the relative humidity is above 90%, the increase range of the thermal conductivity is significant, reaching 25% – 42%. When the density of the rock wool board is 140kg·m⁻³ and 160kg·m⁻³, with the increase of relative humidity, the change of the thermal conductivity is small. Therefore, environmental humidity has a greater impact on the thermal conductivity of rock wool boards with low density, while it has a smaller impact on rock wool boards with high density. This is because rock wool boards with low density have a large porosity, low resistance to water molecule diffusion, and a large amount of moisture absorption. And the thermal conductivity of water is higher than that of rock wool boards. Therefore, when the environmental relative humidity reaches 100%, the thermal conductivity of low – density rock wool boards after moisture absorption increases sharply.

Figure 5 Thermal Conductivity of Rock Wool Boards with Different Densities in Hygroscopic State

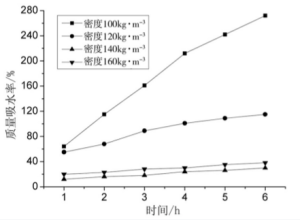

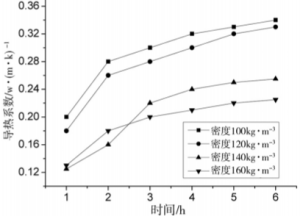

The variation curves of the thermal conductivity of rock wool boards with different densities in the water – absorbing state are shown in Figure 6. As the water – absorbing time prolongs, the thermal conductivity of the rock wool board gradually increases. When the density of the rock wool board is 100kg·m⁻³ and 120kg·m⁻³, the development curves of the thermal conductivity are relatively close. The increase rate is relatively large before 2 hours of water absorption, and it becomes smaller after 2 hours. When the density of the rock wool board is 140kg·m⁻³ and 160kg·m⁻³, the change curves of the thermal conductivity after water absorption are relatively close. Therefore, the smaller the density of the rock wool board, the greater the thermal conductivity in the water – absorbing state. This is because the smaller the density of the rock wool board, the more internal pores there are, and the more water it absorbs. Since the thermal conductivity of water is relatively large, the thermal conductivity of the low – density rock wool board after water absorption is relatively large.

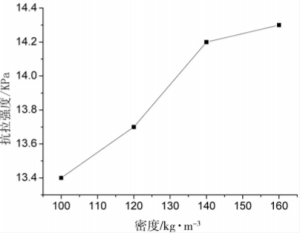

The test results of the tensile strength of rock wool boards with different densities in a dry state are shown in Figure 7. As the density of the rock wool board increases, the tensile strength increases accordingly. This is because the higher the density of the rock wool board, the higher the internal compactness of the rock wool board, and the smaller the porosity, so the higher the tensile strength.

Figure 6 Thermal Conductivity of Rock Wool Boards with Different Densities in Water-Absorbed State

Figure 7 Tensile strength of rock wool boards with different densities in dry state

3 Conclusions

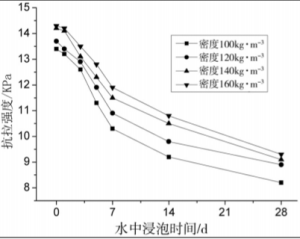

Tests show that the moisture absorption rate of rock wool board decreases with the increase of density, and the water absorption rate of rock wool board also decreases with the increase of density. Under high – temperature conditions, the mass loss rate of rock wool board decreases with the increase of density. In the dry state, the thermal conductivity of rock wool board increases with the increase of density; in the water – absorbed state, the thermal conductivity of rock wool board decreases with the increase of density; in the moisture – absorbed state, rock wool boards with different densities are affected differently by environmental humidity. In the dry state, the tensile strength of rock wool board increases with the increase of density; in the water – absorbed state, the tensile strength of rock wool board decreases, and with the increase of the density of rock wool board, the decrease range becomes smaller.

Figure 8 Tensile strength test results of rock wool boards with different densities in water-absorbed state

Based on the comprehensive test results, it is recommended to select rock wool boards with densities of 140kg·m⁻³ and 160kg·m⁻³ as exterior wall insulation materials.

We focus on the research and development as well as manufacturing

of thermal insulation materials and sealing materials.